I’ve been reading a lot of good agriculture and farm blogs and I wanted to share with you some of the interesting sites I’ve found lately.

The first one about, Future Agricultural Production Limited:

The world’s gross agricultural output needs to increase by 3.4% to meet the growing demand primarily driven by emerging markets across the globe. The two primary ways to increase agricultural production are to either increase the amount of acres planted or increase productivity with technology.

Crop yields have been slowly increasing over time, with the largest increases due to the green revolution and the advancement of hybrid seed technology. Even with the past seed technology, crop yield increases are near 1.0% per year in the U.S while a considerable amount of farmland is being lost to development. Crop production must increase via either new technology or by expanding the amount of cropped land by bringing idle arable land into production.

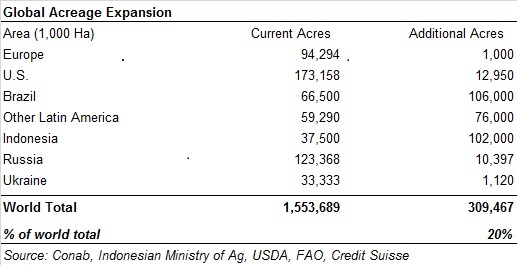

Land to be Brought into Production

The ability to expand arable acres over the next 40 years will be difficult. The best areas for farming have already been identified and are being used for production. The incremental arable acres to be put into production will be on the periphery, with marginal growing conditions and transportation issues.

Presently, the growth of arable farmland has been flat as development of farmland in North America and Europe is offset by expansion in Africa and South America

There are roughly 1.5 billion hectares that are currently being farmed in the world. The FAO estimates that the world has a total of 2.5 billion hectares of “very suitable” or “suitable” for cultivation. 80% of the reserve land is located in Africa and South America.

there are several intesting blogs about agricultural machinery, but why we use agricultural engineering?

you can found the answer here……..,

In this blog we will present some of advanced agricultural machinery.

Tractor

JCB Fastrac 7270 Series

Joining the JCB Fastrac 7000 Series is a new model, the 7270. The tractor is powered by a 6.7-liter Cummins engine for extra power and torque. Tractors in the 7000 Series feature all-round, self-leveling suspension for safe operation up to 43 mph between fields. The 7270 features an all-new chassis, which supports the advanced suspension setup, along with a larger-capacity rear axle and 20,000-lb. rear and optional 7,700-lb. front implement linkage systems. A four-range, six-speed powershift transmission gives the tractor a fingertip-controlled power shuttle, with 24 forward and nine reverse speeds. A touch-screen monitor allows different operating modes to be selected, or the operator can manually shift up and down gears with the seat-mounted joystick. The cab features an operator’s seat with air-suspension. Price: $202,500. Contact: a JCB dealer or visit www.jcbna.com.

Tillage Equipment

Krause Gladiator Precision Tillage System

The Gladiator Precision Tillage System from Krause Corporation is built with ST-Pro row units. The Gladiator series is available in 12-row and 16-row configurations. The frames have the capacity to carry a 1,000-gal. liquid tank and tow an anhydrous tank for fertilizer options. The ST-Pro row units are designed for high-residue situations and provide a uniform residue-free strip with consistent tillage depth control. The Drop Zone nutrient placement system allows farmers to set their fertilizer placement independent of the tillage depth. The patented chain reel technology on the Strik’r soil conditioner breaks clods without plugging while finishing a uniform berm. Changing from field operation to transport is quick and easy, and the flip-and-fold toolbar provides a balanced, safe transport. ST-Pro row units are available with spring reset for rocky conditions.

Seeding Equipment

John Deere DB60 Series Split Row Planter

John Deere adds to its DB Series planter lineup with the DB60 Split-Row Planter. The DB60 combines the flexibility to plant one crop at 30″ rows and a second crop at 15″ rows with the productivity of a bulk-fill planter. The planter configurations include 47-row 15″ and 24-row 30″ planting capabilities. Long parallel arms stagger the rows so they can be locked up and out of the soil during 30″ row planting. The machine is equipped with John Deere’s Central Commodity System (CCS) seed delivery and Pro-Series XP row units. List price: $235,355 with CCS, SeedStar2 monitoring and ProMax40 flat disks and soybean disks. Contact: a John Deere dealer; www.johndeere.com/ag.

Application Equipment

Apache Series self-propelled sprayer

The Apache Series of self-propelled sprayers from Equipment Technologies packs increased horsepower while delivering improved fuel economy. The series features three models outfitted with JCB transmissions and powered by Cummins engines. Models range from 160 hp to 275 hp. The available boom widths include 80′, 90′ and 100′. Machine crop clearance options are 31″, 42″ and 48″. Equipped with Hypro hydraulically driven centrifugal pumps, the sprayers are outfitted with polyurethane or stainless steel tanks, with capacities from 750 gal. to 1,200 gal. The sprayers are compatible with Raven precision ag components.

Harvesting Equipment

New Holland CR9060 Combine

New Holland flexes its harvesting muscle with the introduction of the CX8000 Series and CR9000 Series combines. The three models in the CX8000 Super Conventional Series (CX8070, CX8080 and CX8090) range from 322 hp to 400 hp.The combines use a patented rotary separator that separates nearly all of the grain before it reaches the straw walkers. The feeder and header reverser system can be operated either forward or reverse independent of the threshing unit, allowing the operator to work the slugs into the cylinder in a controlled manner. The 21′ or 24′ overheadstyle unloading augers move grain from the 295-bu. or 330-bu. tank at a rate of 3.2 bu. per second, which is the fastest of any conventional combine. Base price: $254,001. The CR9000 Series (CR9040, CR9060 and CR9070) employs New Holland’s Twin Rotor design to speed separation, boost grain quality and maximize capacity. The three models have turbocharged six-cylinder diesel engines that range from 305 hp to 400 hp.

source: http://www.agweb.com/mymachinery/machinery_showroom/

another good blog about, What Is Precision Farming?

The electronics revolution of the last several decades has spawned two technologies that will impact agriculture in the next decade. These technologies are Geographic Information Systems (GIS) and Global Positioning System (GPS). Along with GIS and GPS there have appeared a wide range of sensors, monitors and controllers for agricultural equipment such as shaft monitors, pressure transducers and servo motors. Together they will enable farmers to use electronic guidance aids to direct equipment movements more accurately, provide precise positioning for all equipment actions and chemical applications and, analyze all of that data in association with other sources of data (agronomic, climatic, etc). This will add up to a new and powerful toolbox of management tools for the progressive farm manager.

Precision farming should not be thought of as only yield mapping and variable rate fertilizer application and evaluated on only one or the other. Precision farming technologies will affect the entire production function (and by extension, the management function) of the farm. A brief overview of the components in precision farming is presented in Figure 1 and listed below.

Yield monitoring

Instantaneous yield monitors are currently available from several manufacturers for all recent models of combines. They provide a crop yield by time or distance (e.g. every second or every few metres). They also track other data such as distance and bushels per load, number of loads and fields.

Yield mapping

GPS receivers coupled with yield monitors provide spatial coordinates for the yield monitor data. This can be made into yield maps of each field.

Variable rate fertilizer

Variable rate controllers are available for granular, liquid and gaseous fertilizer materials. Variable rates can either be manually controlled by the driver or automatically controlled by an on board computer with an electronic prescription map.

Weed mapping

A farmer can map weeds while combining, seeding, spraying or field scouting by using a keypad or buttons hooked up to a GPS receiver and datalogger. These occurrences can then be mapped out on a computer and compared to yield maps, fertilizer maps and spray maps.

Variable spraying

By knowing weed locations from weed mapping spot control can be implemented. Controllers are available to electronically turn booms on and off, and alter the amount (and blend) of herbicide applied.

Topography and boundaries

Using high precision DGPS a very accurate topographic map can be made of any field. This is useful when interpreting yield maps and weed maps as well as planning for grassed waterways and field divisions. Field boundaries, roads, yards, tree stands and wetlands can all be accurately mapped to aid in farm planning.

Salinity mapping

GPS can be coupled to a salinity meter sled which is towed behind an ATV (or pickup) across fields affected by salinity. Salinity mapping is valuable in interpreting yield maps and weed maps as well as tracking the change in salinity over time.

Guidance systems

Several manufacturers are currently producing guidance systems using high precision DGPS that can accurately position a moving vehicle within a foot or less. These guidance systems may replace conventional equipment markers for spraying or seeding and may be a valuable field scouting tool.

Records and analyses

Precision farming may produce an explosion in the amount of records available for farm management. Electronic sensors can collect a lot of data in a short period of time. Lots of disk space is needed to store all the data as well as the map graphics resulting from the data. Electronic controllers can also be designed to provide signals that are recorded electronically. It may be useful to record the fertilizer rates actually put down by the application equipment, not just what should have been put down according to a prescription map. A lot of new data is generated every year (yields, weeds, etc). Farmers will want to keep track of the yearly data to study trends in fertility, yields, salinity and numerous other parameters. This means a large database is needed with the capability to archive, and retrieve, data for future analyses.

source: http://www1.agric.gov.ab.ca/$department/deptdocs.nsf/all/sag1951

another blog about The Future of Internet Connectivity on Farm Equipment?

Smartphones and modems have become an integral part of farming these past few years. These devices have proven to provide an essential means to not only communicate on the farm but the necessary data and information for day-to-day operations. Recently, Precision Ag advancements has been amazing which have included new telematics and RTN offerings. One has to wonder what is next and how technology will efficiently and economically communicate between machines and the internet.

The other day we were conducting a precision ag project and noted the use of 4 cellular plans on the same machine. These plans included 2 handling RTN correction data transfer for our RTK receivers, 1 providing internet access for another technology, and my Smartphone which I was using to text and e-mail while operating the machine. Sounds pretty far fetched to have 3 data plans to make all the technology on a single machine work plus the operator maintaining a cell phone. However, it is not unrealistic to have 2 to 4 cellular plans (one being a personal cell phone) required to run a machine today equipped with precision ag technology. The expense of these plans can add up quickly over time as we can attest to here at Auburn.

Solutions? One solution would be using a Smartphone as the “Hotspot” for all required communication on machines. Farmers and employees already require cell phones so why not have it as the main communication device for everything. Plus, studies show Smartphone usage has increased among farmers. So the idea would be as soon as someone enters the cab, all technologies quickly connect through the “Hotspot” and have uninterrupted communication once 4G matures to a level which permits voice and data to be simultaneous in rural areas. We would then have only 1 required plan for the machine which moves with a person to perform other communication tasks on the farm. Data transmission requirements for most machine applications is rather low, so 4G along with a Smartphone could help reduce dedicated data plans for some technologies.

There is no doubt, internet connectivity in machine equipment will continue to expand based on company offerings and future technologies being developed. I think cellular communication will be a primary means of internet access for these ag technologies due to its coverage area and accessibility. If one considers the potential of having multiple, dedicated data plans for their machines plus covering the expense of employee cell phones, it can become expensive. Further, it could grow into a management concern if using different cellular carriers. Thereby, reducing this complexity of data plans could be addressed in the future by using Smartphones which allows communication for both voice but also wireless data transfer on machines with 1 device. This concept might be easier to envision versus making reality, but it would simplify life for precision ag practitioners.

source: http://www.aces.edu/anr/precisionag/

another one about, Information Systems Technology in Agriculture

Information systems are computer applications to support the operation of an organization: operating, installation, and maintenance of computers, software, and data

Changes in agricultural technology are influenced by internal factors (experience and needs of oneself) and external factors (government policies, extension) changes in agricultural technology affect socio-economic state of society, but does not change the social status of the customs.

Along with improving the quality of the resources of farmers and agricultural actors and the advancement of information and communication technologies as well as consideration of the effectiveness and efficiency of the dissemination of information, one of the solutions offered in order to address issues of agricultural technology transfer and knowledge is the use of information and communication technologies (ICTs) are for the extension farm known as “cyber extension” which is the use of on-line network, computer and digital interactive multimedia to facilitate the dissemination of agricultural technologies. This model is considered highly strategic because it can increase access to information for farmers, extension workers, researchers in both research institutes and in universities as well as the extension manager. In addition to using “cyber extension” of agricultural extension is currently also use multiple information systems for rural communities to support the business and agricultural businesses as well as repair of household economies of rural communities. Multiple communication yan used as systemtelephone, wireless information systems, off-talk communication, FAX, CATV, personal computer communication, video tex, satellite communication systems, Internet (EI-net), television telephone system. With the technology used in agricultural extension is expected to improve extension services to farmers’ activities in providing advance yangsemakin agricultural innovation and help the agricultural extension officers play a role in coordinating the elements of agriculture in the region to establish cooperation denganpihak parties or relevant authorities.

The technology used is relatively simple and less its application is still on target, this is because the regeneration of extension is not running, the interest of farmers to technology and finding information is still weak, because the media use of agricultural information has not been widespread.

source: http://www.goyangkarawang.org/2011/08/information-systems-technology-in.html

Leave a comment